01 - Rough Diamond Acquisition

Through our strong partnerships with leading lab-grown rough diamond manufacturers worldwide, we ensure a consistent and unparalleled supply of polished diamonds for our clients. Rough diamonds are sourced globally and undergo meticulous processing, adhering to strict quality control standards, before being classified and graded by our expert team.

02 - Rough Diamond Assortment

Leveraging our extensive procurement capabilities, we possess deep insights into diamonds of various origins and qualities. Our expert team assort rough diamonds based on the desired polished outcomes, considering factors such as color, clarity, size, and cut. Specialized assortments are created to add significant value to the rough goods, catering to niche markets.

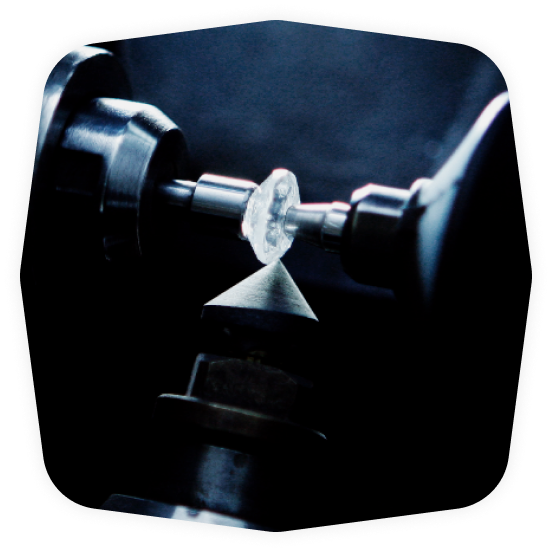

03 - Diamond Planning & Marking

Diamond planning and marking form the core of our manufacturing process. Rough stones are meticulously planned and marked based on factors like shape, size, inclusion positions, and market demands. Advanced machinery is utilized to mark diamonds, ensuring precise clarity and brilliance. The clarity and brilliance of the diamond are enhanced by minimizing inclusions and positioning them strategically.

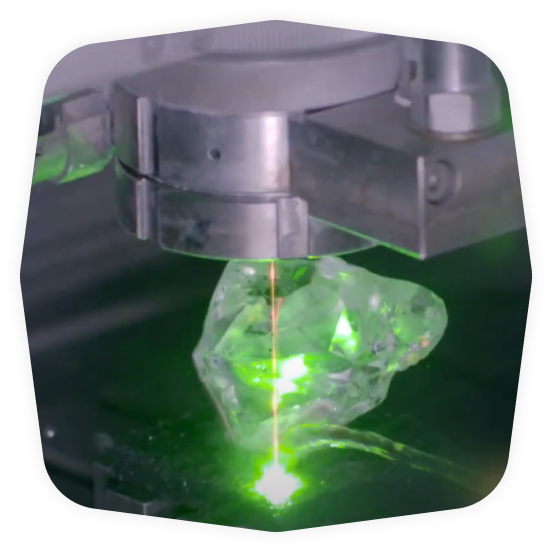

04 - Cleaving

Cleaving and sawing processes divide diamonds into smaller pieces. Depending on the diamond's characteristics, it may be cleaved or sawn. Cleaving is a critical process, especially for large and valuable stones, as it can affect the diamond's integrity. Sawing, often done through laser machines, has advanced significantly in recent times, ensuring precision and minimal loss.

05 - Laser System

Following cleaving or sawing, diamonds undergo thorough checks before proceeding to the next stage of the process.

06 - Boiling Process

Boiling is a cleaning method used to remove impurities from diamonds processed under the laser system. Diamonds are washed in sulfuric and nitric acid to ensure thorough cleaning and inspection at each manufacturing stage.

07 - Lotting

Lotting involves preparing small packets of diamonds based on size for distribution to various factories. This department plays a crucial role in allocating diamonds to factories based on their size requirements.

08 - Bruting

Bruting shapes rough diamonds into desired forms, involving processes like rough blocking, top blocking, and bottom blocking. It ensures optimal weight retention and removes internal imperfections, enhancing the diamond's appearance and value.

09 - Polishing

Polishing is the final step in diamond cutting, giving the diamond its ultimate luster and brilliance. A well-polished diamond is free from visible flaws and exhibits exceptional sparkle. Surface facets are meticulously polished to achieve maximum beauty before the diamond proceeds to the grading department.

Copyright © 2024, All Right Reserved ..VALABROTHERS